QSC locking system

Standard for quick coupler locks under the tiltrotator

Standardized locking procedures reduce the risk of dangerous mistakes by creating a uniform and clear procedure for securing the attachment. This significantly increases safety, especially when changing attachment, thanks to the ground pressure sensor that prevents the bucket lock from opening when the bucket is hanging freely in the air. In addition, a visual and audible warning system helps to further increase safety by warning with light and sound when coupling.

This standardization applies to all engcon tiltrotators, regardless of the attachment used. In addition, the system fulfils the requirements of standards for safe attachments, giving users the confidence to work with the highest safety standards.

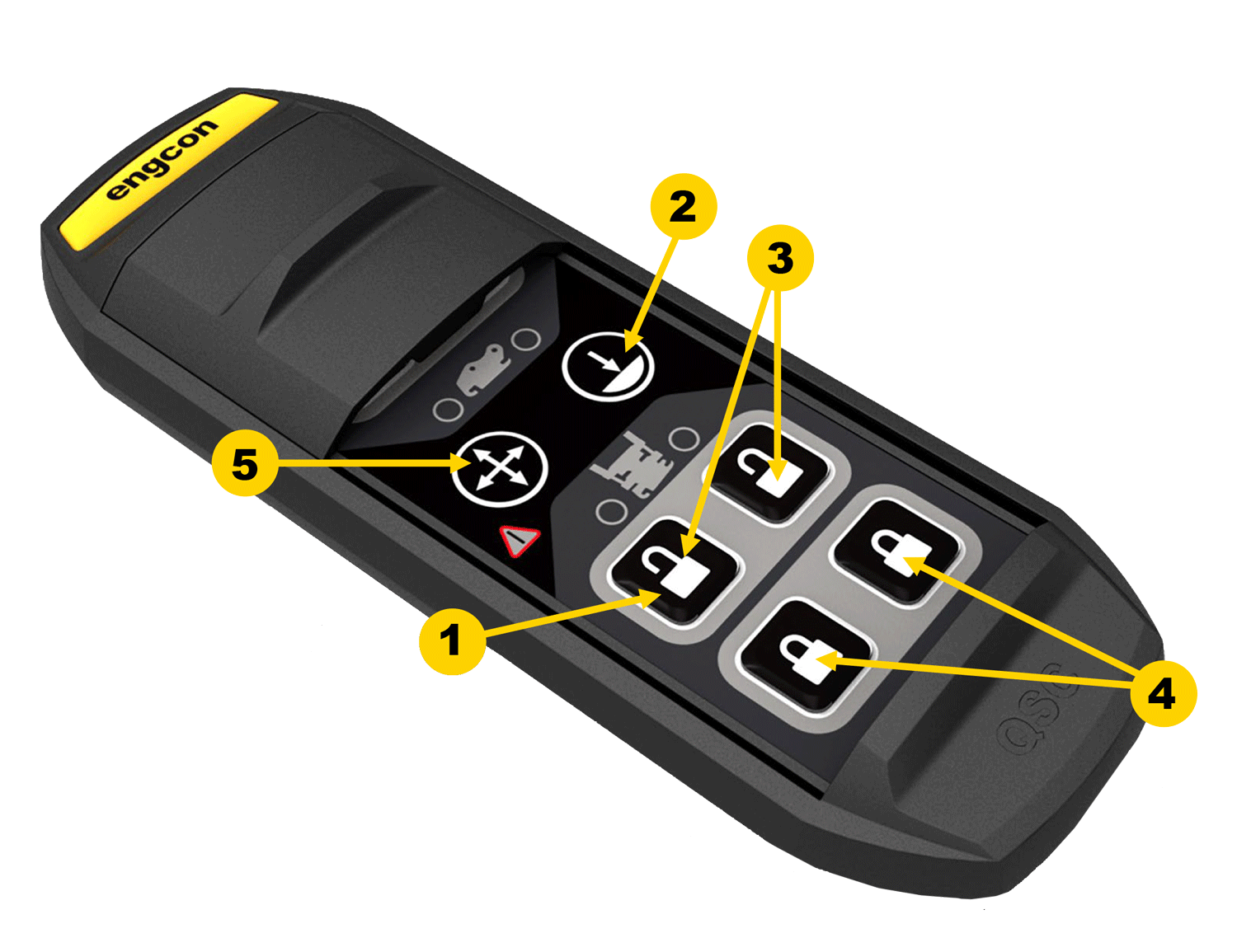

The locking panel is designed with a 'self-guiding' function where the correct button is illuminated, making it easy and intuitive for the user to operate. This standardises operation regardless of the make or model of the excavator, reducing the risk of confusion or misuse.

Added value

- Standard beneath all engcon tiltrotators with the DC2 control system, regardless of the machine coupler

We ship everything required for the installation of locking function under the tiltrotator - Standardized locking procedure reduces the risk of dangerous mistakes.

- Increased safety with ground pressure sensor

- Increased functionality during the lock/open sequence. (Tilt/rotation)

- Lower cost for those who want the machine coupler connected in the same way.

- Additional safety features that limit the machine are available as an optional extra.

- Control panel

- The locking system is an accessory on the machine hitch

- Locking system – standard

Fast and safe

operation

- Activate the system

- Place the bucket/tool on the ground until the symbol is extinguished

- Open the quick coupler lock(s)

Disconnect and change tool - Close the quick coupler lock

- Disable machine limiter (Optional)

Indicators during lock sequence

- Ground pressure sensor

(extinguished on ground contact = ok to unlock quick coupler lock) - Sensors tool shafts front/rear

(Applies to Q-Safe. For other mounts, contact engcon)

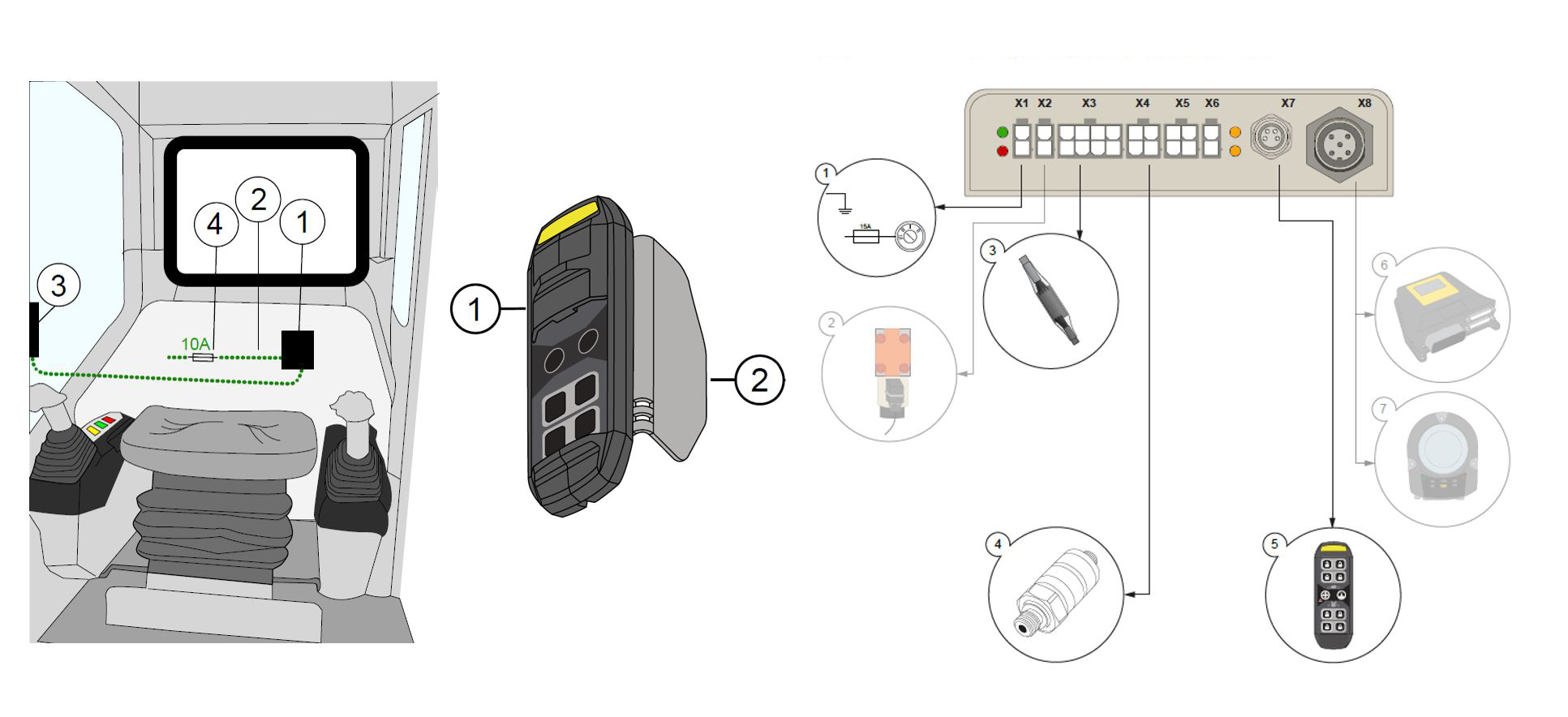

Assembly

Connect cabling to the QCM electronics module.

Overview - Connection of cables in electronics module.

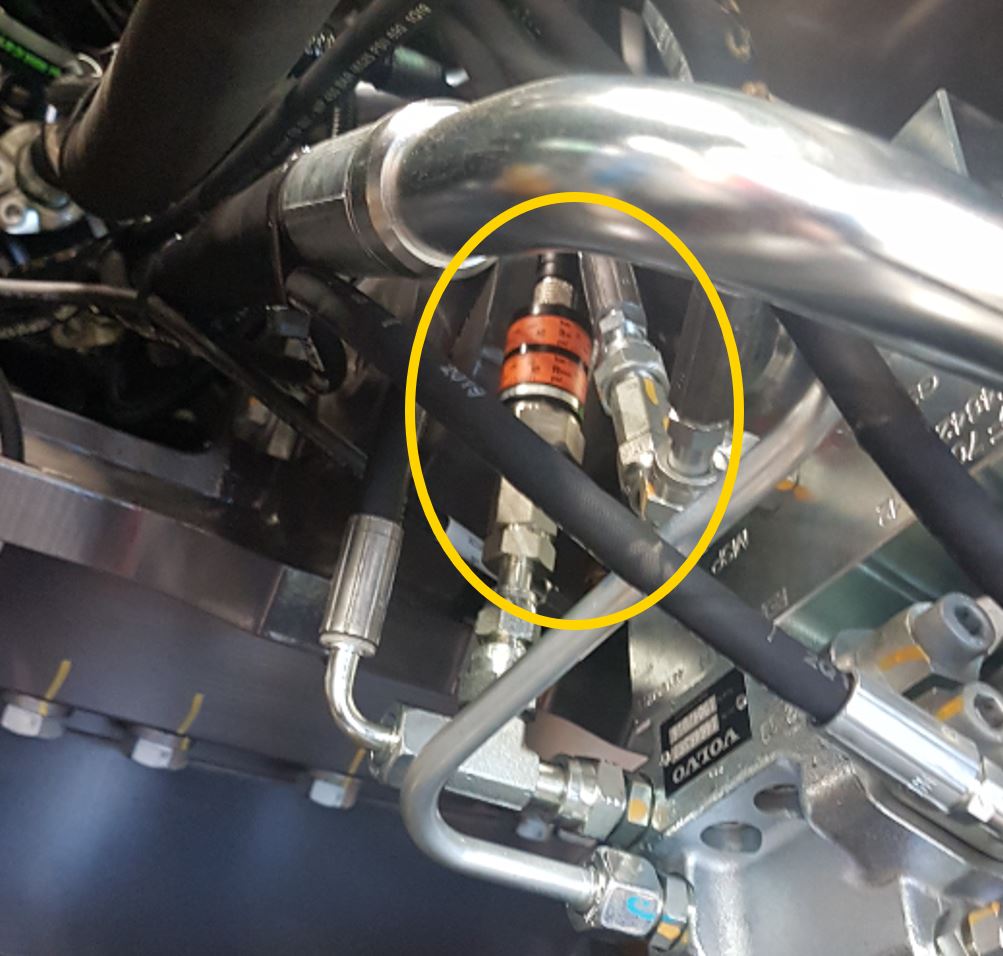

Installation ground pressure sensor

- Installed with T-connector or directly in the valve block.

(in closed socket protected for hose breakage) - Easy sensor calibration

- Withstands high pressure

404 - Page not found

We couldn't find the page you're looking for.

An error has occurred

Try downloading the page again to see if the error recurs.

An error has occurred

We could not connect you to the Internet