Experience the engcon DC2

engcon’s step less proportional control system for tiltrotators, engcon DC2 (Digging Control), combines high safety with the latest technology and several new functions to improve operation. engcon DC2 is suitable for all machine brands on the market.

Smart app saves time and money

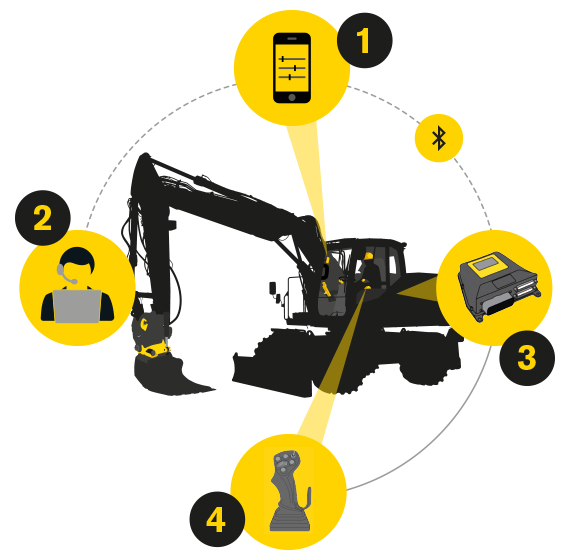

1. Smartphone

Connect your Smartphone to the DC2 via Bluetooth and switch between different operator profiles and tools or enter speed settings. Call the support desk and get remote support via the mobile phone network.

2. Remote support

DC2 troubleshooting and calibration via the mobile phone network.

3. The DC2 proportional control system

DC2 proportional control system for tiltrotators fits all excavators. It is available with wheel and track steering, as well as boom control via the machine’s joysticks.

Maximum safety – certified and approved according to ISO 13849-1 and 2006/42/EC.

4. Full-functionality

Ergonomic MIG2 joystick is optimized for demanding use and can, when combined with the DC2, be used with up to 6 rollers and 14 buttons on two joysticks.

engcon DC2 – safety* in the system

engcon DC2 meets the new international machine safety standard EN ISO 13849-1. Each joystick button and roller is monitored by double signals. These signals are alternate and crosswise, and are the only sure way of detecting a short circuit in the cable, something which is not standard in traditional control systems. Control over the hydraulics has been improved, with additional on/off valves and pressure monitors to prevent simple faults leading to dangerous situations. If a problem occurs in the hydraulics system, the machine will switch to ”safe mode”. The operator is warned and receives a clear error message on the control box’s built in display.

* In accordance with the safety requirements, the DC2 is certified specifically for each individual machine model. This takes place continually as the systems are sold. For further information, please contact your engcon dealer.

The right settings – with the market’s first remote support system

Via PC/USB or smartphone/bluetooth you can adjust the settings and the speed of the controls which enables you to maximize the control of the machine.

Developed using the latest technology, engcon DC2 offers remote support. When a fault is indicated, you contact the remote support which then takes control of the system via a server link and an app in your Smartphone. The remote support can carry out troubleshooting, basic calibration and track larger faults, saving both time and money.

- Make adjustments of the control leavers in just 10 minutes.

- More detailed information for service technicians.

- Quick and easy service and support of the system from the manufacturer.

engcon DC2 is designed to facilitate remote support by the use of smartphone or computer via the mobile network

New functions and advantages to improve operation

engcon DC2 offers exceptional precision and flexibility to the way you control your machine. It is easy to use and install on your machine and has a number of new functions to optimize machine control.

- Several system outlets with the option of track control and wheel steering and also, moving the boom.

- Steering with up to six rollers (Danfoss and L8 joysticks).

- Smart joystick adapter for steering/controlling all the tiltrotator’s functions. Can be fitted quickly and easily to the original levers and does not affect the CE mark.

Work on a new level

– easy to get started!

404 - Page not found

We couldn't find the page you're looking for.

An error has occurred

Try downloading the page again to see if the error recurs.

An error has occurred

We could not connect you to the Internet