EC-OIL – AUTOMATIC QUICK HITCH SYSTEM

EC-OIL IN YOUR LANGUAGE

Interrested in knowing more about EC-Oil? By choosing your language down below you will be taken to your country page.

Switch jobs in an instant – from the cab

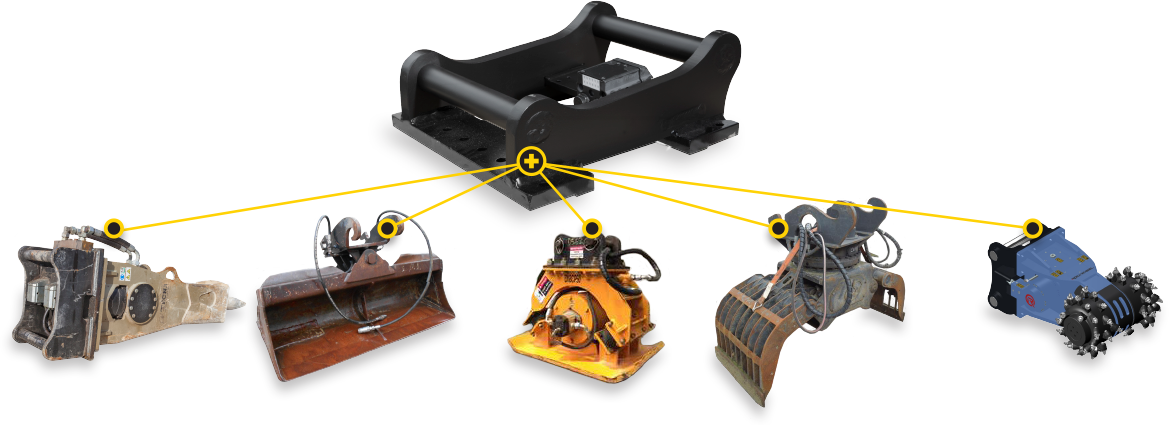

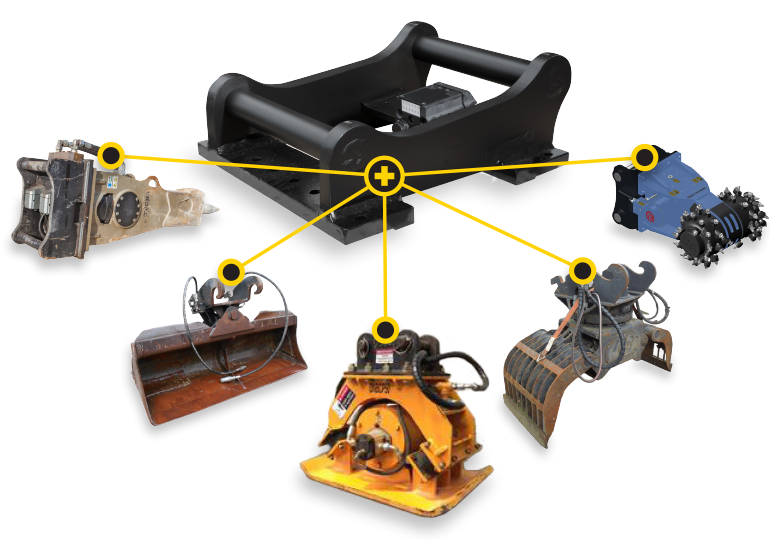

EC-Oil is the key to our system. It allows for quick switching of hydraulic tools and connection/disconnection of the tiltrotator for increased breakout force. The EC-Oil automatic hydraulic connector is now standard. In some jobs, this can save an hour or more every day compared to manual connection – and time is money.

As a supplier we can help you with a total solution – everything from control systems, machine hitches, tiltrotators and associated tools. Use EC-Oil for instant tool and attachment changes directly from the cab.

With EC-Oil on the machine hitch, above and below the tiltrotator and on the tool itself, you can disconnect from the tiltrotator and connect the machine hitch directly to a hydraulic or mechanical tool whenever you need extra breakout force.

This also saves weight, which means fuel savings and improved total efficiency. Together they create a system of tools that allow you to work quickly, efficiently and profitably. EC-Oil is designed for the highest operational reliability in demanding environments.

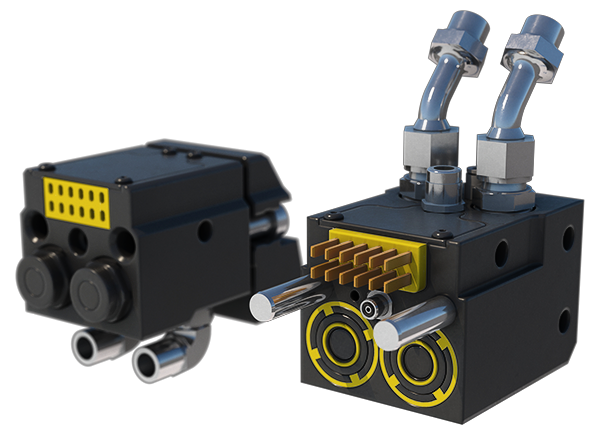

The EC-Oil™ has no visible hoses or electrical cables that move around when connecting. This reduces the risk for pinch damage and wear. The engcon quick hitch system handles the connection of pressurised tools at full system pressure.

The proprietary oil and electrical connections are designed to be even better at withstanding the tough conditions excavators often have to work in.

The connectors are designed for tough handling, as proven through destructive testing at 1600 bar operating pressure and field tests in difficult environments. EC-Oil™ also connects to central lubrication automatically.

EC-Oil in a nutshell

- EC-Oil is standard with all purchases of engcon machine hitches and tiltrotators.

- This lets you change hydraulic tools in around ten seconds without leaving the cab.

- Connects hydraulic tools automatically.

- Can be retrofitted to all types of hydraulic tools, regardless of manufacturer.*

- Requires no installation for return oil.

- Extremely durable connectors allow tool connection at full system pressure.

- Drip-free system = Lower environmental impact.

- Reduces problems with manual hydraulic connectors.

* Check specifications and flow requirements.

Automatic quick hitch system – our standard

When you order an engcon S40–S80 machine hitch we include the EC-OIL automatic oil connector in the machine hitch, the upper section of the tiltrotator, and in the tiltrotator quick hitch (S40–S80).

EC-Oil is ALWAYS included as standard, on all engcon hydraulic tools with S40–S80.

TIRED OF GETTING OUT OF THE CAB TO CHANGE THE HYDRAULICS?

Now there’s a better alternative!

With engcon’s automatic quick hitch system you can switch hydraulic tools without leaving your seat!

If nothing goes wrong, connecting a tool manually takes around 90 seconds. With EC-Oil, the same tool change takes about 10 seconds. The number of times we switch attachments naturally varies, but certain tasks require around 50 tool changes a day. On days like that, EC-Oil will save you more than one hour of labour!

%20IMG_6891_1+.jpg)

”With engcon’s automatic quick hitches I can connect my hydraulic tools in just 10 seconds without leaving the cab. It saves time, money and effort!”

Holger Herzberg from Albert Brecht switches between a hammer and bucket up to 50 times a day.

The old way

Swithes/day | Connect hydraulics manually | Total/day |

|---|---|---|

48 | 90 sec | 72 min |

The engcon way

Swithes/day | Connect hydraulics with Q-Safe + EC-Oil | Total/day |

|---|---|---|

48 | 10 sec | 8 min |

Save time, save money!

Automatic quick hitch system

Connect without leaving the cabin:

Use the quick hitch and tiltrotator (1) or disconnect the tiltrotator and connect your tools directly on the quick hitch when maximum maximum lift or breakout force is needed (2).

All without leaving the cabin!

TOOLS | Hydraulic

Hydraulic attachment bracket

Adapt it for your existing tools

404 - Page not found

We couldn't find the page you're looking for.

An error has occurred

Try downloading the page again to see if the error recurs.

An error has occurred

We could not connect you to the Internet